Full Assembly Capability

Fabrifoam’s Full Assembly manufacturing capability offers a complete in-house solution — from custom components to finished, ready-to-ship products. Our experienced production team and advanced fabrication systems provide the flexibility and precision needed to serve a variety of industries, especially within medical and therapeutic product manufacturing.

This end-to-end service allows us to design, produce, and assemble your product entirely within our facility, ensuring efficiency, consistency, and superior quality control at every stage.

From Concept to Completion

Fabrifoam’s Full Assembly process supports every phase of production:

- Design and Prototyping: Collaborate with our in-house engineers to refine your concept.

- Component Manufacturing: Create custom shapes, layers, or features using cutting, seaming, and lamination techniques.

- Assembly and Integration: Combine materials through advanced RF welding and ultrasonic welding for durable, precise seams.

- Final Packaging and Labeling: Deliver finished products tailored to your private label or OEM specifications.

This integrated approach ensures that your product meets regulatory and functional standards while maintaining a cost-effective production cycle.

Advanced Welding Capabilities

RF Welding

Our radio frequency (RF) welding systems attach hook components, reinforce seams, and create strong, uniform bonds in flexible materials. Fabrifoam’s customized RF equipment provides a competitive edge, meeting the diverse product and performance needs of clients across industries.

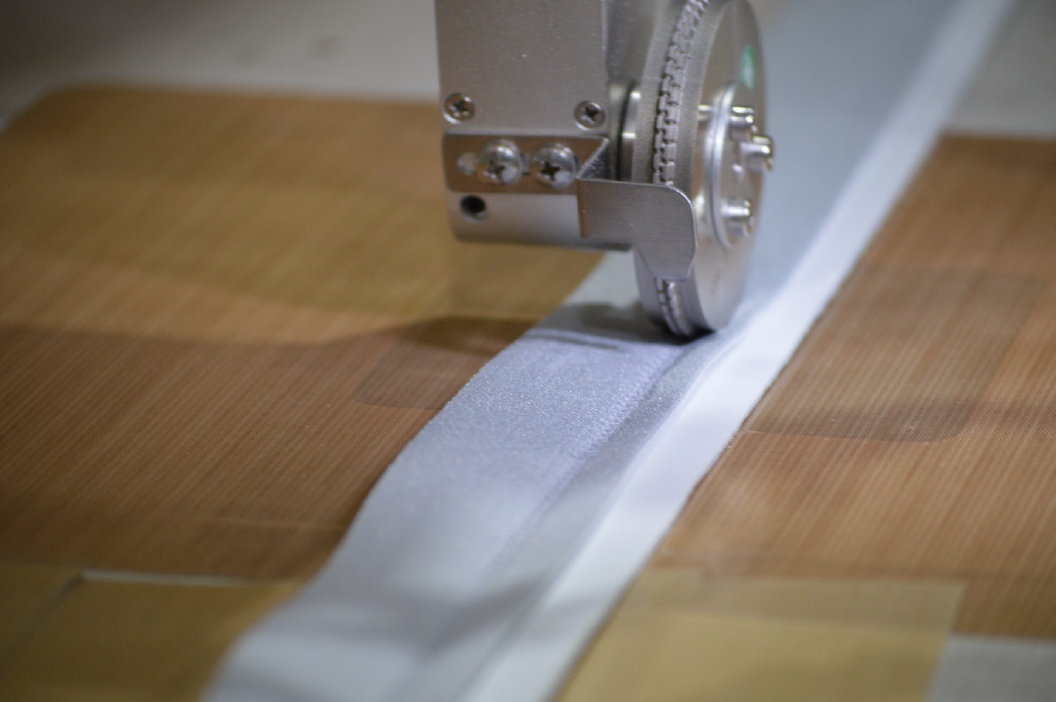

Ultrasonic Welding

Our ultrasonic welding systems use high-frequency vibration to join fabrics and foams cleanly and efficiently. This technology allows for attaching engineered plastic components, creating seams, or combining multiple substrates with precise control and uniformity.

Both processes ensure high-quality seams and consistent results while maintaining the comfort, performance, and integrity of Fabrifoam materials.

Why Choose Fabrifoam for Full Assembly

Fabrifoam’s complete product assembly process gives you more than manufacturing — it provides a trusted production partnership. Our capabilities ensure:

- Consistent quality from raw material to final packaging

- Seamless integration of multiple manufacturing processes

- Faster turnaround and reduced logistical complexity

- Scalable production for OEM and private label customers

With our full assembly capabilities, you can rely on Fabrifoam to transform your concept into a market-ready product with precision, reliability, and efficiency.

Request a Quote or More Information

Ready to take your concept from design to delivery? Fabrifoam’s team is ready to help. Whether you need complete OEM production or custom component integration, our experts can provide a tailored solution for your project.

Contact us today to request a quote, discuss your assembly needs, or learn how Fabrifoam’s advanced manufacturing can streamline your production.